Findings Published in Proceedings of the National Academy of Sciences

Seawater electrolysis, the process of extracting oxygen and hydrogen out of water, was first discovered in the early 19th century.

Throughout the 1800s, scientists made advances in hydrogen production and seawater electrolysis even captured the imagination of novelist Jules Verne. His book “Twenty Thousand Leagues Under the Sea,” famously featured the Nautilus, a submarine powered by electricity from seawater.

In the 20th century, hydrogen mostly extracted from natural gas was used to power blimps, buses, cars and even make rocket fuel. But this process of producing hydrogen is energy intensive and results in a very large amount of carbon dioxide emissions which contributes to climate change.

Fast forward to the present day, scientists are now trying to develop technologies using seawater electrolysis to produce sustainable green hydrogen that will not exacerbate the global shortage of freshwater or increase carbon emissions.

Researchers from the Texas Center for Superconductivity at the University of Houston (TcSUH) have developed an NiFe (nickel and iron)-based electrocatalyst that interacts with CuCo (copper cobalt) to create high-performance seawater electrolysis.

In a paper published by Proceedings of the National Academy of Sciences, they noted that current technology used to produce hydrogen from seawater electrolysis at an industrial scale is hampered by three main factors: Seawater is corrosive, shortening the lifetime of the catalysts; electrolysis using current catalysts may create chlorine gas, which needs to be prevented; and the electrocatalysts currently used for oxygen evolution reaction (OER) do not satisfy the requirement to make it worth the cost.

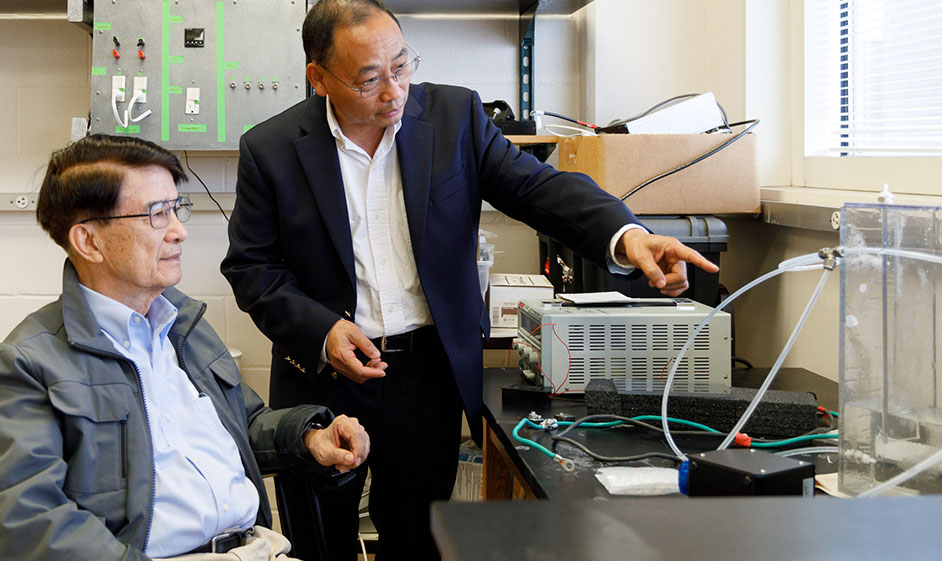

The research team, led by physics professor and TcSUH director Zhifeng Ren, found this multi-metallic electrocatalyst to be one of the best performing among all reported transition- metal-based OER electrocatalysts, and suggests it can boost the development of seawater electrolysis technology.

The process and technology being developed by Ren’s team have the potential to lower hydrogen production to $1 per kilogram in the future, with the expected wider deployment of solar and wind power to drive the electrolysis producing hydrogen from seawater, Ren noted.

“To produce a kilogram of hydrogen, it currently requires about 50 kilowatt hours of electrical power. If the cost is 10 cents per kilowatt-hour using power from the grid, that makes your cost $5.00 per kilogram of hydrogen just for the power consumed. That's too expensive,” Ren said. “However, in the future, if you use surplus electrical power from wind or solar, it goes down to less than 1 cent per kilowatt-hour. Then you could get it a $1.00 per kilogram or lower, making it economically viable.”

Each kilogram of hydrogen produced using seawater electrolysis can also yield 9 kilograms of pure water when hydrogen is used subsequently, which is important because many places in the world also need access to freshwater, he added.

There are plans to explore the commercialization of this catalyst. Ren’s research team is working with Element Resources, a Houston-based company that works on green hydrogen projects.

“They are particularly interested in seawater because they are looking for areas where large amounts of freshwater are not readily available,” Ren said.

The world will need clean hydrogen as the energy transition moves forward because the way it is currently produced through gasification is not clean and it has environmental consequences, Ren said.

“So, we need to make sure there is a new way to produce hydrogen gas that meets society’s needs when it comes to the environment and making sure there is also a reliable supply available,” he added.

- Karn Dhingra, University Media Relations