University of Houston Researchers Exploring the Bounds of Room-Temperature Superconductivity

In the simplest terms, superconductivity between two or more objects means zero wasted electricity. It means electricity is being transferred between these objects with no loss of energy.

Many naturally occurring elements and minerals like lead and mercury have superconducting properties. And there are modern applications that currently use materials with superconducting properties, including MRI machines, maglev trains, electric motors and generators.

Usually, superconductivity in materials happens at low-temperature environments or at high temperatures at very high pressures. The holy grail of superconductivity today is to find or create materials that can transfer energy between each other in a non-pressurized room-temperature environment.

If the efficiency of superconductors at room temperature could be applied at scale to create highly efficient electric power transmission systems for industry, commerce, and transportation, it would be revolutionary. The deployment of the technology of room temperature superconductors at atmospheric pressure would accelerate the electrification of our world for its sustainable development. The technology allows us to do more work and use less natural resources with lower waste to preserve the environment.

There are a few superconducting material systems for electric transmission in various stages of development. In the meantime, researchers at the University of Houston are conducting experiments to look for superconductivity in a room-temperature and atmospheric pressure environment.

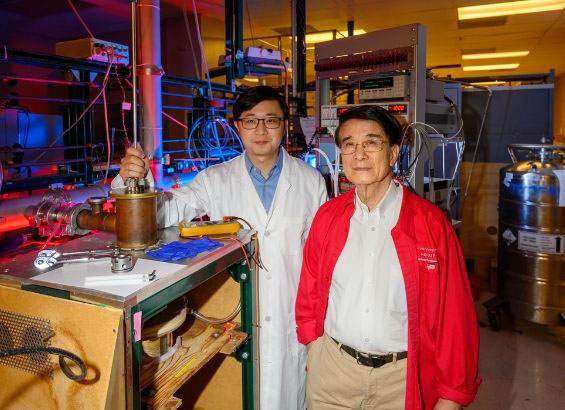

Paul Chu, founding director and chief scientist at the Texas Center for Superconductivity at UH and Liangzi Deng, research assistant professor, chose FeSe (Iron (II) Selenide) for their experiments because it has a simple structure and also great Tc (superconducting critical temperature) enhancement under pressure.

Chu and Deng have developed a pressure-quench process (PQP), in which they first apply pressure to their samples at room-temperature to enhance superconductivity, cool them to a chosen lower temperature, and then completely release the applied pressure, while still retaining the enhanced superconducting properties.

The concept of the PQP is not new, but Chu and Deng’s PQP is the first time it’s been used to retain the high-pressure-enhanced superconductivity in a high-temperature superconductor (HTS) at atmospheric pressure. The findings are published in the Journal of Superconductivity and Novel Magnetism.

“We waste about 10% of our electricity during transmission, that's a huge number. If we had superconductors to transmit electricity with zero energy wasted, we would basically change the world, transportation and electricity transmission would be revolutionized, “Chu said. “If this process can be used, we can create materials that could transmit electricity from the place where you produce it all the way to places thousands of miles away without the loss of energy.”

Their process was inspired by the late Pol Duwez, a prominent material scientist, engineer and metallurgist at the California Institute of Technology who pointed out that most of the alloys used in industrial applications are metastable or chemically unstable at atmospheric pressure and room temperature, and these metastable phases possess desired and/or enhanced properties that their stable counterparts lack, Chu and Deng noted in their study.

Examples of these materials include diamonds, high-temperature 3D-printing materials, black phosphorus and even beryllium copper, which is notably used to make tools for use in high explosive environments like oil rigs and grain elevators.

“The ultimate goal of this experiment was to raise the temperature to above room temperature while keeping the material’s superconducting properties,” Chu said. “If that can be achieved, cryogenics will no longer be needed to operate machines that used superconducting material like an MRI machine and that’s why we’re excited about this.”

- Karn Dhingra, University Media Relations